Vacuum drying of basil seed gum

In this article, the method of vacuum drying in the laboratory is explained by means of a study on the preparation of gum from basil.

The following summarizes the published study in the International Food Research Journal detailing the use of the Memmert vacuum oven VO in the test determining effect of the various drying methods on the texture and rheological properties of basil seed gum. It is one of the many applications of drying ovens.

Background

The study is conducted by The National Center for Biotechnology Information who discussed the topic: technical properties of aqueous systems. Here, the distribution of water-soluble gums helps to understand improved gelling and thickening properties in food products. Thus, it is found essential “to understanding of functional characteristics of gum in order to select the appropriate one based on the scope of application”. The properties further help understand emulsification of flavors, elasticity and retention of moisture. All this allows for the extraction of hydrocolloids from the seeds. The study is found worthwhile due to abundance and cost effectiveness.

Ocimum basilicum L.

Now comes the subject of the research: Ocimum basilicum L. which can be found in parts of Asia, Europe, and the Middle East. This is a mucilaginous plant. Its seed has functional properties like that of commercial food hydrocolloids. The basil seed gum potentially became a relatively new source of hydrocolloid. It is explained that the texture and rheological properties are affected by the methods and condition of the plant’s gums by way of extraction, purification and drying.

The drying process is quite extensive. It is noted that a wide net of molecular weight is cast during it. This relies on the type and conditioning of drying which, in turn, affects the viscosity. Another qualitative factor is the color of the dried product. The drying techniques applied commonly are: oven drying, spouted bed drying, microwave vacuum drying, freeze drying, spray drying and vacuum drying – which is the Memmert vacuum drying oven VO that has been used in this experiment.

A key importance for having this study is because no such detailed study exists to such an extent. The researchers, Salehi and Kashaninejad, state:

“There is no study available in the literatures that investigate the effect of different drying techniques and temperature on the rheological and textural properties of basil seed gum. Hence, the purpose of present study was to investigate the influence of different drying techniques (oven drying (40-80°C), freeze drying and vacuum oven drying) on the rheological and textural properties, and color changes of basil seed gum”.

Resources and methods

Extraction of gum

Firstly, the basil seed gums were bought in Gorgan, Iran and afterwards, the extraction process took place.

- Soaked in distilled water with a pH 7 and 20:1 water to seed ratio

- Soaking carried for 20 minutes at a temperature of 25 °C

- Seeds passed into extractor for separation of the hydrocolloid off swollen seeds

- The extracted mucilages are filtered

- Filtered mucilage with 0.06% w/w is taken as control

Oven drying

Next up, comes the topic of oven drying. Here the steps are as follows.

- A Memmert drying oven is used

- By way of convection, the distribution of the basil seed gum were dried at 40 °C to 80 °C at 10 °C increments

- The total time period of drying was 48 hours

- Samples are milled and filtered through mesh sieve

- Milled powder is kept in airtight container for storage

Freeze drying

Following this, comes the process involving freeze drying which is part of several applications.

- Cups are filled with basil seed gum dispersions

- They are placed inside the freeze dryer

- The dryer runs for 48 hours

- Samples are milled and passed via mesh sieve

- Milled powder is stored in airtight bottles

Vacuum oven drying with Memmert vacuum oven VO

As the final type of drying, the researchers use a Memmert vacuum drying oven VO.

- The extracted seed gums are dried in the vacuum drying oven

- The time period of drying is 48 hours

- The values of vacuum pressure and temperature are 100mbar and 50 °C

- Samples are later milled and passed through a mesh sieve

- Milled powder is weighed and subsequently stored in airtight bottle

Memmert vacuum oven VO.

How does a vacuum oven work? To delve deeper and find out about laboratory vacuum ovens, sign up for our newsletter for the latest product news.

Sample preparation

The sample preparation is conducted for consideration of the texture, viscometer and image analysis possibilities.

- Basil seed gum are distributed in distilled water

- 2 concentration values are used. 0.6% (w/w) for calculation of shear rate dependency and image processing; 3% for study of textural properties of seed gums

- The solutions are maintained for 24 hours at room temperature to fulfill gum hydration

Results

Apparent viscosity

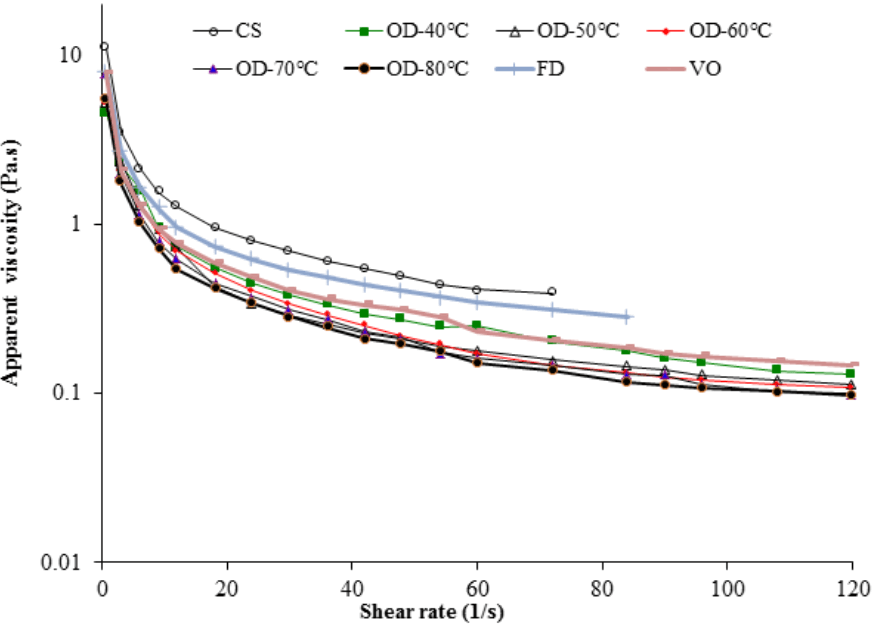

Effect of different drying methods on apparent viscosity of Basil seed gum solution as a function of shear rate; control sample (CS), oven drying (OD), freeze drying (FD), and vacuum oven drying (VO).

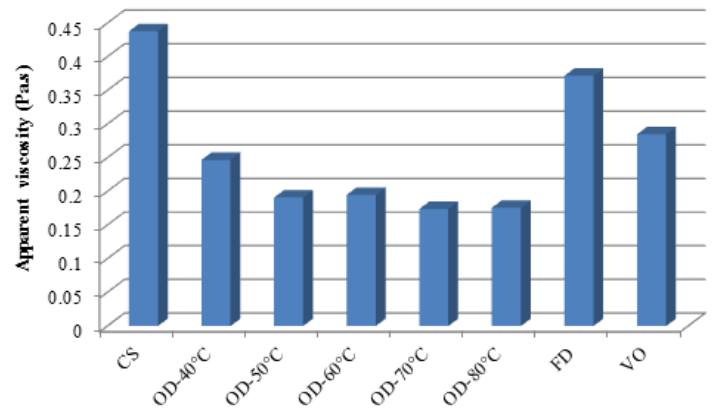

Effect of different drying techniques on apparent viscosity of Basil seed gum (shear rate=54s-1); control sample (CS), oven drying (OD), freeze drying (FD), and vacuum oven drying (VO).

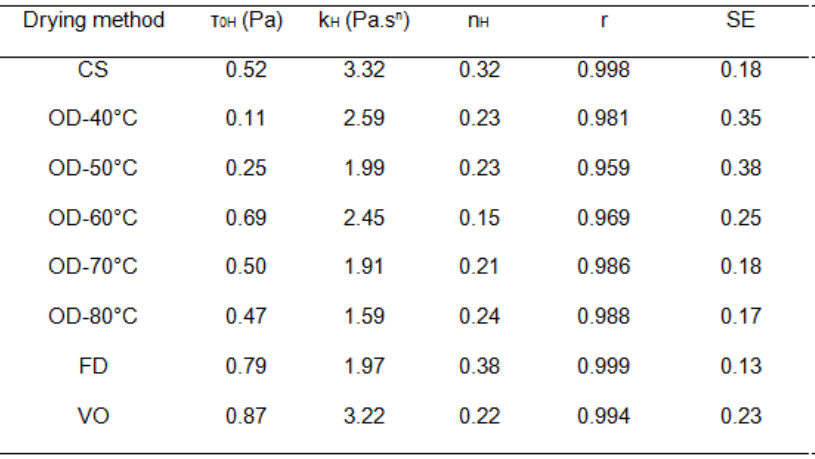

The rheological parameters obtained by fitting the experimental shear stress-shear rate data to the Heschel-Bulkley model at different drying methods. Control sample (CS), Oven drying (OD, 50-80°C), freeze drying (FD), vacuum oven (VO).

Textural properties

Drying methods and its effect on textural properties. Oven drying (OD, 50-80°C), freeze drying (FD), vacuum oven (VO).

Color assessment

Color assessment is helpful as image analysis can objectively help researchers determine the quality of dried samples.

“Color usually is the first quality parameter that is evaluated by consumers and is critical in the acceptance of the product”. – Salehi and Kashaninejad

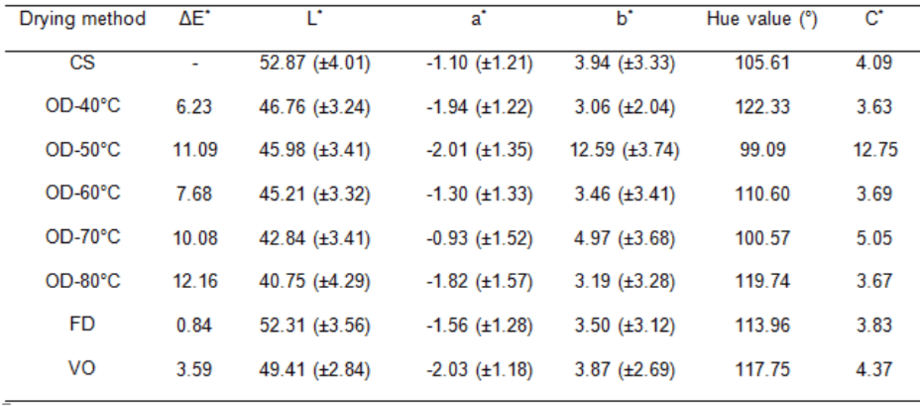

Table showing the different drying methods and its effect on color change of basil seed gum. Control sample (CS), Oven drying (OD, 50-80°C), freeze drying (FD), vacuum oven (VO); L: brightness (+100)/darkness (+0), a: redness (+60)/greenness (-60) coordinate, b: yellowness (+60)/blueness (-60) coordinate, C: chroma.

About Memmert vacuum oven VO

Memmert GmbH + Co.KG, operating out of Schwabach and manufacturing from Büchenbach, produces the vacuum oven VO as part of its diverse heating and drying oven range.

It offers features such as:

- Temperature range up to +200 °C

- Vacuum control range: 5 to 1100 mbar

- 3 model sizes (29 to 101 litres volume)

- 1 model variant: TwinDISPLAY

- Anti-splinter; VDE-tested door construction for all models

- Pump control: Optimised rinsing of the pump membrane as well as signal output for switching the pump ON/OFF according to requirements

- Optional: Pump base cabinet and energy-efficient vacuum pump

- Nearly exclusive use of high-quality, rust-resistant and easy to clean stainless steel for interior and exterior housing

- Precise and homogenous temperature control thanks to a product-specific heating concept

- A wide range of options for programming and documentation using interfaces, integrated data loggers and the AtmoCONTROL software

- 3 years guarantee worldwide